Sensing Technologies

For more than thirty years, the engineers at Sensing Technologies have been working closely with customers in the HVAC, refrigeration, food service, pool/spa, medical, automotive, and military/defense markets. Quality is our highest priority. We recognize that in this era of reduced engineering resources, many companies are looking for a way to extend their engineering talent. It is for that reason that we encourage our customers to think of us a partner in the design, development, and manufacture of high quality, precision temperature sensors and probe assemblies.

When it comes to measuring temperature, no two applications are exactly alike. At STI, we believe that the proper design of a temperature sensor requires a collaborative effort between the customer and the manufacturer. The process starts with a thorough understanding of the application requirements, including temperature range, accuracy, thermal response and electrical isolation. Equally important, however, are the environmental requirements such as moisture and chemical resistance, vibration, freeze/thaw cycling, and thermal shock.

applications

- Rooftop A/C and Split systems

- Chilled water systems

- Compressor motor winding sensors

- Condenser, evaporator and duct sensors

- MRI / CAT scan machines

- Blood analyzers

- Gas chromatography

- Incubators and skin temperature sensors

- Reach-in and walk-in refrigerator cases

- Ovens and food warming equipment

- Coffee brewers and juice dispensers

- Ice cube and ice cream machines

- Inlet and outlet water temperature

- Outside air temperature

- Freeze protection sensors

- Solar, water and air sensors

- Intake and outside air temperature

- Coolant and emission sensors

- Transmission oil and engine oil temperature

- Water level sensors

- Oil and fuel temperature

- Cold water inlet and hot water outlet

- Geothermal systems

- Residential and commercial heat pumps◦Oil and fuel temperature ◦Cold water inlet and hot water outlet ◦Geothermal systems ◦Residential and commercial heat pumps

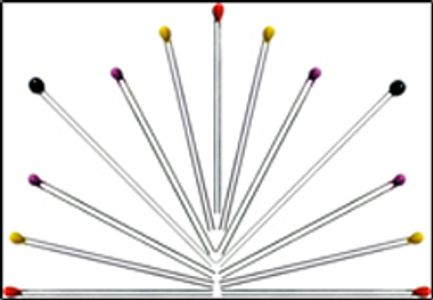

Sensors

General Purpose Probe Assemblies

General Purpose Probe Assemblies

General Purpose Probe Assemblies

Surface Temperature Sensors

Threaded and Flange Mount Probe Assemblies

General Purpose Probe Assemblies

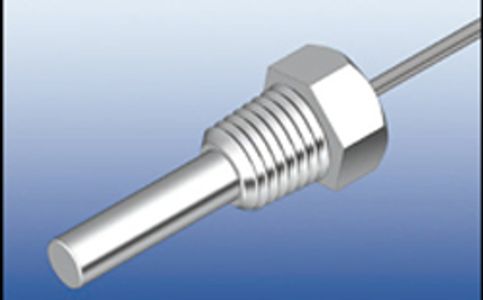

Threaded and Flange Mount Probe Assemblies

Threaded and Flange Mount Probe Assemblies

Threaded and Flange Mount Probe Assemblies

Special Purpose Probe Assemblies

Threaded and Flange Mount Probe Assemblies

Threaded and Flange Mount Probe Assemblies

Design Process

Step 1: Sensor Selection

Step 1: Sensor Selection

Step 1: Sensor Selection

At STI, we offer a wide variety of sensing elements, including epoxy coated chip and glass encapsulated thermistors, thin film and wire wound platinum RTDs, voltage to temperature transducers, and current to temperature transducers. Our sensors are used from -50°C to +500°C with acccuracies as close as ±0.10°C.

Step 2: Housing Design

Step 1: Sensor Selection

Step 1: Sensor Selection

A properly designed housing is critical to sensor performance. It locates the element in direct contact with the medium to be measured and protects the sensor from damage while allowing for the fastest possible thermal response. In addition to having a large selection of standard list precision closed end tubes, we offer a wide variety of machined stainless steel, brass, copper, and plastic housings.

Step 3: Modeling and Prototyping

Step 4: Testing and Final approval

Step 4: Testing and Final approval

Throughout the design process, we use 3D modeling as our means of communicating ideas to and getting feedback from our customers. Once the model is complete and approved, we often provide prototype units for test and evaluation.

Step 4: Testing and Final approval

Step 4: Testing and Final approval

Step 4: Testing and Final approval

Sensing Technologies utilizes NIST traceable temperature measuring equipment to insure accuracy at tolerances down to ±0.01°C. MIL standard testing includes shock and vibration, temperature, humidity, corrosion, and altitude.